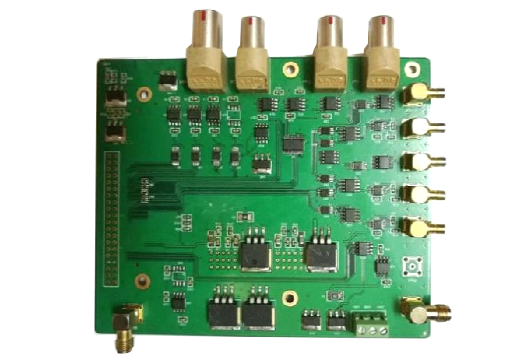

Multi-channel data acquisition card

DAQ-100: Nano-Scale High-Precision Multi-Channel Data Acquisition and Control Card

Product Description

1. Product Overview

The DAQ-100 is a high-performance data acquisition and conversion expansion card specifically designed for nano-scale laser processing, micro-displacement precision control, and high-sensitivity photoelectric detection. Serving as the core signal hub of a micro/nano positioning system, the DAQ-100 integrates multi-channel, high-resolution analog-to-digital conversion (ADC) and high-dynamic-range digital-to-analog conversion (DAC) modules on a single platform.

Through an industrial-grade HSMC interface, the DAQ-100 seamlessly interfaces with ZYNQ FPGA–based controllers and other FPGA host platforms, enabling full closed-loop control from optical signal acquisition to precision piezoelectric actuator (PZT) drive.

2. Key Advantages

Ultra-Low-Noise Power Architecture

The system supports ±24 V industrial supply input with wide dynamic range. An internal ultra-low-noise, high-precision linear regulation architecture generates seven independent precision power rails (+12 V, −12 V, +5 V, −5 V, +3.3 V, −3.3 V, +2.5 V, etc.). This architecture fundamentally suppresses ripple and switching noise, ensuring signal integrity at full 16-bit resolution.

High-Dynamic, Fast-Response Drive Capability

Equipped with four 16-bit high-precision DAC channels operating at up to 1 MSPS, the DAQ-100 is optimized for piezoelectric actuator (PZT) control. It delivers excellent voltage linearity and fast transient response, enabling real-time nano-scale displacement compensation.

Flexible Multi-Range Signal Acquisition

Multiple programmable analog input ranges (0–5 V, 0–10 V, −10–0 V) support a wide variety of sensors, including quadrant photodiodes (QPDs) and photodiodes. With parallel multi-channel sampling, the system enables real-time monitoring of reflected intensity, transmitted intensity, and laser power normalization signals.

Industrial-Grade Physical Connectivity

Professional LEMO connectors, along with SMB / SMA / SMC RF connectors, are employed for all critical analog interfaces. This industrial-grade interconnection scheme minimizes signal loss and significantly enhances electromagnetic compatibility (EMC) in electrically noisy environments.

3. Technical Specifications

Analog Input (ADC)

Analog Output (DAC)

System Interfaces

Power and Signal Integrity

4. Application Areas

The DAQ-100 is a high-performance data acquisition and conversion expansion card specifically designed for nano-scale laser processing, micro-displacement precision control, and high-sensitivity photoelectric detection. Serving as the core signal hub of a micro/nano positioning system, the DAQ-100 integrates multi-channel, high-resolution analog-to-digital conversion (ADC) and high-dynamic-range digital-to-analog conversion (DAC) modules on a single platform.

Through an industrial-grade HSMC interface, the DAQ-100 seamlessly interfaces with ZYNQ FPGA–based controllers and other FPGA host platforms, enabling full closed-loop control from optical signal acquisition to precision piezoelectric actuator (PZT) drive.

2. Key Advantages

Ultra-Low-Noise Power Architecture

The system supports ±24 V industrial supply input with wide dynamic range. An internal ultra-low-noise, high-precision linear regulation architecture generates seven independent precision power rails (+12 V, −12 V, +5 V, −5 V, +3.3 V, −3.3 V, +2.5 V, etc.). This architecture fundamentally suppresses ripple and switching noise, ensuring signal integrity at full 16-bit resolution.

High-Dynamic, Fast-Response Drive Capability

Equipped with four 16-bit high-precision DAC channels operating at up to 1 MSPS, the DAQ-100 is optimized for piezoelectric actuator (PZT) control. It delivers excellent voltage linearity and fast transient response, enabling real-time nano-scale displacement compensation.

Flexible Multi-Range Signal Acquisition

Multiple programmable analog input ranges (0–5 V, 0–10 V, −10–0 V) support a wide variety of sensors, including quadrant photodiodes (QPDs) and photodiodes. With parallel multi-channel sampling, the system enables real-time monitoring of reflected intensity, transmitted intensity, and laser power normalization signals.

Industrial-Grade Physical Connectivity

Professional LEMO connectors, along with SMB / SMA / SMC RF connectors, are employed for all critical analog interfaces. This industrial-grade interconnection scheme minimizes signal loss and significantly enhances electromagnetic compatibility (EMC) in electrically noisy environments.

3. Technical Specifications

Analog Input (ADC)

| Parameter | Specification |

| Resolution | 16-bit (high-precision, parallel multi-channel sampling) |

| Channel Count | 7 high-precision channels + multiple low-speed monitoring channels |

| Maximum Sampling Rate | 100 kSPS |

| Input Ranges | 0–5 V / 0–10 V / −10–0 V (configurable) |

Analog Output (DAC)

| Parameter | Specification |

| Resolution | 16-bit (primary drive) / 8-bit (high-speed modulation) / 10–12 bit (auxiliary) |

| Channel Count | 4 primary output channels + multiple auxiliary outputs |

| Update Rate | 1 MSPS (16-bit) / up to 200 MSPS (high-speed modulation) |

| Target Applications | PZT actuation, laser power modulation |

System Interfaces

| Item | Specification |

| Host Interface | HSMC standard connector (compatible with ZYNQ / FPGA platforms) |

| External Connectors | LEMO, SMA, SMB, SMC, 10-pin headers |

Power and Signal Integrity

| Item | Specification |

| Input Supply | ±24 V DC |

| Internal Rails | 8 precision linear-regulated voltage outputs |

| Signal Integrity | High SNR, ultra-low temperature drift |

4. Application Areas

- Nano-Scale Laser Processing

Ultra-short pulse modulation (down to 10 ns) and precise laser power compensation. - Micro-Displacement Precision Control

Driving PZT X/Y/Z multi-axis stages, achieving nano-scale step resolution within a 200 μm travel range (voltage resolution down to 0.5 mV). - High-Energy Physics and Optical Detection

High-precision acquisition of quadrant photodiode signals for accurate beam spot centroid locking. - Semiconductor Inspection

Synchronous high-speed digitization and analysis of transmitted and reflected optical intensity signals.

5. System Integration Example

In a typical nano-fabrication system, the DAQ-100 operates in conjunction with a ZYNQ-series control platform:

6. Customization Options

In addition to standard configurations, custom DAQ solutions are available. Input/output types, resolution, sampling rates, and interface options can be tailored to meet specific system integration requirements.

In a typical nano-fabrication system, the DAQ-100 operates in conjunction with a ZYNQ-series control platform:

- Downlink Control:

A 1 MSPS / 16-bit DAC drives the PZT controller, enabling ultra-precise stage displacement control. - Uplink Acquisition:

A 100 kSPS ADC continuously feeds back signals from quadrant photodiodes and photomultiplier tubes (PMTs), forming a high-bandwidth feedback loop. - High-Speed Calibration:

Onboard high-speed signal channels provide 256-level grayscale laser power modulation, ensuring consistent and repeatable processing accuracy.

6. Customization Options

In addition to standard configurations, custom DAQ solutions are available. Input/output types, resolution, sampling rates, and interface options can be tailored to meet specific system integration requirements.