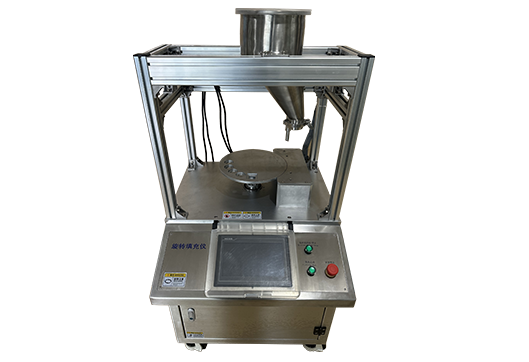

Powder Rotary Filling Instrument

Product Description

1. Product Overview

The Powder Rotary Filling Instrument is a precision laboratory-scale system specifically developed to simulate powder filling processes in traditional Chinese medicine (TCM) tablet compression and capsule filling operations. The instrument integrates a variable-speed powder feeding system, a dual-mode scraper assembly (static and forced modes), and a flexible die-based filling module within a compact experimental platform.

By accurately reproducing the powder filling conditions of industrial rotary tablet presses, the system enables qualitative and quantitative characterization of powder flowability, mass uniformity, and filling efficiency under dynamic conditions. It provides critical experimental data and technical insights for TCM formulation development, pharmaceutical process optimization, and manufacturing scale-up.

2. Core System Architecture

2.1 Variable-Speed Powder Feeding System

The Powder Rotary Filling Instrument is a precision laboratory-scale system specifically developed to simulate powder filling processes in traditional Chinese medicine (TCM) tablet compression and capsule filling operations. The instrument integrates a variable-speed powder feeding system, a dual-mode scraper assembly (static and forced modes), and a flexible die-based filling module within a compact experimental platform.

By accurately reproducing the powder filling conditions of industrial rotary tablet presses, the system enables qualitative and quantitative characterization of powder flowability, mass uniformity, and filling efficiency under dynamic conditions. It provides critical experimental data and technical insights for TCM formulation development, pharmaceutical process optimization, and manufacturing scale-up.

2. Core System Architecture

2.1 Variable-Speed Powder Feeding System

- Configuration:

Composed of a feed hopper, flow-rate control valve, and powder transfer channel. - Functionality:

Supports a powder loading capacity of 100 g to 500 g, ensuring stable and controllable powder discharge. - Technical Advantage:

Adjustable flow paths accommodate powders with different bulk density, particle size distribution, and cohesiveness, making the system suitable for a wide range of herbal and excipient materials.

This subsystem is designed to replicate powder filling environments encountered in tablet presses operating under different process conditions:

- Interchangeable Design:

Static scraper blades and forced (dynamic) scraper assemblies can be rapidly exchanged using predefined positioning interfaces on the metal support plate. - Forced Scraping Technology:

The dynamic scraper module integrates dual rotating paddles, driven by an independent motor with a speed range of 0–100 rpm, mechanically enhancing powder mobilization and significantly improving the filling performance of poorly flowing herbal powders. - Micro-Scale Observation Interface:

A reserved cavity beneath the support plate allows integration of high-speed imaging systems, enabling real-time visualization and micro-scale analysis of powder flow behavior during die filling. - Wear Protection and Contamination Control:

Arc-shaped resin wear pads are applied at contact interfaces between the scraper and the rotating disc, preventing metal-to-metal abrasion, reducing maintenance requirements, and minimizing the risk of product contamination.

2.3 High-Precision Filling and Flexible Die System

3. Technical Highlights

- Precision Filling Disc:

A high-flatness metallic rotary disc with a radius of 160 mm, ensuring repeatable and stable filling conditions. - Multi-Geometry Die Cavities:

- Four circular die cavities with an inner diameter of 22.02 mm, evenly distributed along the disc circumference.

- One standard square cavity (29.10 × 29.10 mm) positioned at the disc periphery.

- Flexible and Customizable Dies:

The die system adopts a recessed modular insert structure, allowing rapid replacement with cylindrical, elliptical, heart-shaped, or other customized cavity geometries. Die depth and effective volume are adjustable, enabling accurate simulation of different dosage forms and TCM prescription characteristics.

3. Technical Highlights

- High Process Fidelity

Faithfully reproduces the powder filling mechanism of rotary tablet presses, serving as an ideal transition platform from bench-scale trials to pilot-scale pharmaceutical production. - Integrated Qualitative and Quantitative Analysis

Combines high-speed visual flow analysis with gravimetric evaluation of filled mass uniformity, supporting comprehensive powder performance assessment. - Intelligent Control Interface

Equipped with an integrated PLC-based touchscreen control system for precise digital setting of motor speed and operating modes. - Robust and Maintainable Construction

Built with an industrial-grade aluminum profile frame and AISI 304 stainless steel housing, offering excellent corrosion resistance, cleanability, and suitability for pharmaceutical laboratory environments.

4. Technical Specifications

5. Application Areas

| Performance Parameter | Specification |

| Rotary Disc Radius | 160 mm |

| Powder Load Capacity | 100 g – 500 g |

| Scraper Modes | Static scraping / Forced (dynamic) scraping, interchangeable |

| Dynamic Scraper Speed | 0 – 100 rpm (stepless adjustment) |

| Standard Die Dimensions | Circular: Ø22.02 mm / Square: 29.10 × 29.10 mm |

| Die Geometry | Cylindrical, elliptical, heart-shaped, irregular (customizable) |

| Materials | AISI 304 stainless steel + aluminum profiles + resin wear pads |

| Control System | Touchscreen-based intelligent control system |

- TCM Powder Modification and Formulation Studies

Evaluation of the effects of glidants, binders, and granulation processes on powder filling behavior. - Pharmaceutical Process Optimization

Determination of optimal combinations of scraper mode and disc rotational speed for improved die filling consistency. - Manufacturing Scale-Up Assessment

Pre-validation of powder filling performance under laboratory conditions prior to full-scale production. - Quality Control and Stability Testing

Batch-to-batch consistency evaluation of powder filling properties as part of process capability and quality assurance studies.