LVDT Calibration System

CAL-LVDT-100 / RY-LVDT-200

High-Precision Automated LVDT Calibration System

Product Description

I. Product Overview

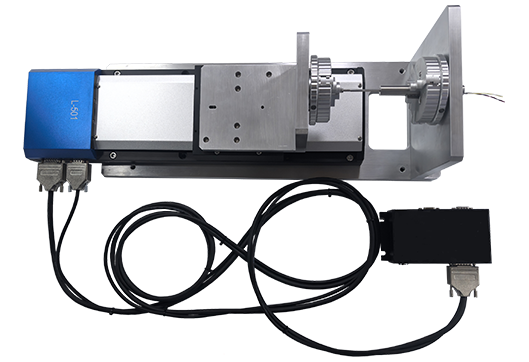

The CAL-LVDT-200 is a bespoke, metrology-grade calibration platform specifically engineered for Linear Variable Differential Transformer (LVDT) sensors. Built around the L501 linear actuator unit with an integrated high-precision linear optical encoder (grating scale), the system combines precision mechanical architecture with a closed-loop control topology. It enables fully automated, high-fidelity calibration for a wide array of LVDT specifications.

Compared to conventional 25mm manual calibration rigs, this system provides an extended operational stroke, a higher degree of automation, and superior coaxial stability. It serves as a premier solution for sensor R&D, production-line characterization, and metrological verification.

II. Core Advantages

1. Sub-micron Precision with 200mm Extended Calibration Stroke

The CAL-LVDT-200 is a bespoke, metrology-grade calibration platform specifically engineered for Linear Variable Differential Transformer (LVDT) sensors. Built around the L501 linear actuator unit with an integrated high-precision linear optical encoder (grating scale), the system combines precision mechanical architecture with a closed-loop control topology. It enables fully automated, high-fidelity calibration for a wide array of LVDT specifications.

Compared to conventional 25mm manual calibration rigs, this system provides an extended operational stroke, a higher degree of automation, and superior coaxial stability. It serves as a premier solution for sensor R&D, production-line characterization, and metrological verification.

II. Core Advantages

1. Sub-micron Precision with 200mm Extended Calibration Stroke

- The drive unit features a 200mm wide-range effective stroke, accommodating the calibration requirements of long-displacement sensors.

- Leveraging a 0.1μm motion resolution and ±0.2μm bi-directional repeatability, the system provides an ultra-precise displacement reference standard for calibration cycles.

- Utilizing a dual L-shaped aluminum alloy mounting plate paired with a 3-jaw self-centering chuck, the system ensures secure and centered sensor fixturing.

- The positioning interfaces achieve 0.01mm-level concentricity, with a total system coaxiality of ≤0.05mm post-clamping. This high degree of geometric alignment inherently eliminates offset errors and parallax deviations during the metrological process.

- The adjustable clamping range of the chuck accommodates various LVDT geometries with diameters up to 48mm and strokes up to 200mm.

- This "universal-fit" design significantly enhances throughput for multi-model sensor batches without the need for frequent jig changeovers.

- The drive unit is secured to a high-flatness aluminum alloy baseplate via precision dowel pins, ensuring long-term structural determinism.

- The high-rigidity architecture ensures zero-backlash and zero-redundancy during displacement transfer, safeguarding the integrity and consistency of the calibration datasets.

- Employs a high-performance closed-loop stepper controller, ensuring high-bandwidth dynamic response and deterministic positioning.

- The dedicated automation software allows for pre-set step increments and cycle counts, automatically executing data acquisition and linearity/hysteresis analysis.

III. Technical Specifications

IV. Application Fields

| Parameter | Specification | Remarks |

| Effective Stroke | 200 mm | Extended range |

| Motion Resolution | 0.1 μm | Sub-micron precision |

| Bi-directional Repeatability | ±0.2 μm | Metrology-grade consistency |

| Coaxiality (Post-clamping) | ≤0.05 mm | Minimizes cosine errors |

| Sensor Diameter Compatibility | ≤48 mm | Universal 3-jaw chuck |

| Feedback Mechanism | Linear Optical Encoder | High-resolution grating scale |

| Control Mode | Closed-loop Servo-Stepper / Automated Suite | Deterministic control |

| Base Material | High-flatness Aluminum Alloy | Specialized surface finish |

| Total System Mass | Approx. 7 kg | Portable/Benchtop design |

IV. Application Fields

- Sensor Manufacturing: Full-scale calibration and Final Acceptance Testing (FAT) for displacement sensors.

- Metrology Institutes: Periodic calibration of high-precision LVDTs and inductive gauging probes.

- Aerospace & Precision Engineering: Micro-displacement verification and thermo-mechanical stability experiments for high-precision sub-systems.