Magnetic resistance sensor

MAG310 High-Performance Magnetoresistive Sensor System

Product Description

I. Product Overview

The MAG310 is an industrial-grade, high-performance magnetoresistive sensor system specifically engineered for Directional Drilling, Measurement While Drilling (MWD), and Logging While Drilling (LWD) applications. Integrating advanced Anisotropic Magnetoresistive (AMR) sensing technology, high-precision signal conditioning, and real-time attitude determination algorithms, the system provides stable and continuous subsurface magnetic field data under extreme borehole conditions. It serves as the core functional unit for real-time monitoring of the downhole Toolface Angle.

II. Core Advantages III. Technical Features

IV. Technical Specifications

V. Application Scenarios

The MAG310 is an industrial-grade, high-performance magnetoresistive sensor system specifically engineered for Directional Drilling, Measurement While Drilling (MWD), and Logging While Drilling (LWD) applications. Integrating advanced Anisotropic Magnetoresistive (AMR) sensing technology, high-precision signal conditioning, and real-time attitude determination algorithms, the system provides stable and continuous subsurface magnetic field data under extreme borehole conditions. It serves as the core functional unit for real-time monitoring of the downhole Toolface Angle.

II. Core Advantages

- Superior Thermal Stability: Purpose-built for extreme downhole environments, supporting continuous and stable operation at 175°C. It exhibits excellent thermal deterministic performance and negligible zero-point offset drift.

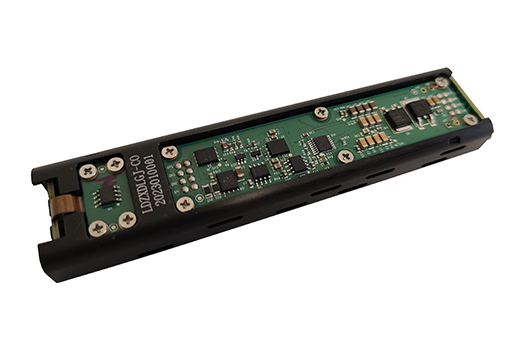

- Highly Integrated Modular Architecture: Utilizes advanced Rigid-Flex PCB technology. The power management and digital acquisition modules are independently distributed and interconnected via flexible substrates. This design enhances mechanical decoupling against vibration and shock while optimizing internal space utilization within precision downhole instruments.

- Full-Chain Digital Signal Processing: Features an embedded high-performance Floating-Point Unit (FPU) and a 24-bit high-resolution digital data link. The system performs real-time acquisition and processing of tri-axial (XYZ) magnetic field vectors, delivering high-precision toolface data outputs directly.

- Ultra-Low Power Topology: Typical system power consumption is maintained below 1.75W, significantly reducing parasitic self-heating and the electrical load on the Bottom Hole Assembly (BHA) power system, thereby extending the mission life of battery modules.

- Precision Tri-axial Metrology: Integrates three high-performance magnetoresistive sensors in a spatial orthogonal layout to achieve precise omni-directional magnetic vector capture.

- Intelligent Actuator Control: Equipped with automated sensor driving and Set/Reset (Flip-current) self-calibration circuitry, ensuring the sensor remains in an optimal magnetic state even in complex electromagnetic environments.

- Wide-Input Power Management: Supports an ultra-wide 12V to 36V DC supply range. The onboard precision power management system provides multi-channel, ultra-low-noise regulated outputs for the digital interface and the analog front-end (AFE), ensuring maximum signal spectral purity.

- Redundant Communication Interfaces: *Dual-channel redundant CAN-bus ensures real-time telemetry and mission-critical reliability.

- Integrated low-power, high-speed differential receiver circuits facilitate robust data exchange in long-distance or high-noise subsurface environments.

- High-Reliability Storage & Thermal Monitoring: Features 64 Mbit of industrial-grade non-volatile memory (NOR Flash) for redundant logging of critical operational parameters. An integrated wide-range temperature sensor enables active environmental thermal compensation and system health monitoring.

IV. Technical Specifications

| Parameter | Specification |

| Operating Temperature Range | -40°C to +175°C |

| Measurement Axes | Tri-axial (X, Y, Z Orthogonal) |

| Supply Voltage | 12V to 36V DC |

| Full-Scale Range (FSR) | ±5 Gauss |

| Resolution | 20 µGauss |

| Sensitivity | 1.2 mV/V/Gauss |

| Linearity Error | 0.15% to 2.30% FS |

| Bridge Resistance | 2.5 kΩ (Typical) |

| Total System Power | < 1.75W |

| Communication Interface | 2 × CAN Bus / High-speed Differential |

| Storage Capacity | 64 Mbit |

| Digital Resolution | 24-bit ADC Resolution |

| Physical Architecture | Rigid Power Board + Digital/Sensing Rigid-Flex PCB |

V. Application Scenarios

- Oil & Gas Exploration: MWD/LWD systems for directional and horizontal wellbore steering.

- Subsurface Directional Boring: Attitude guidance for Trenchless Pipe Laying and Horizontal Directional Drilling (HDD).

- Mineral Exploration: High-precision downhole compasses and directional surveying instruments.

- Extreme Environmental Monitoring: Industrial magnetic field detection tasks requiring sustained operation at 175°C.