LVDTSensor

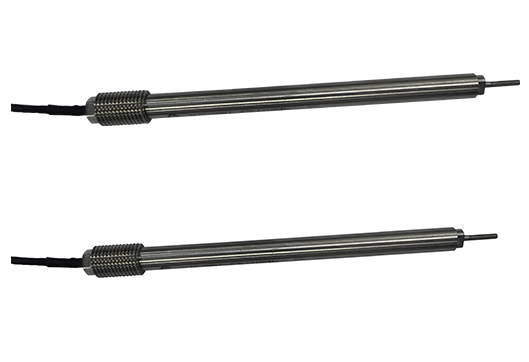

LS40: 40mm Range High-Precision LVDT Displacement Sensor

Product Description

一、Core Overview: Precision Displacement Sensing Beyond Limits

The LS40 is a high-performance linear variable differential transformer (LVDT) sensor engineered for industrial automation, aerospace actuation, and structural health monitoring. With a 40mm full-scale measurement range, it provides non-contact displacement sensing based on electromagnetic induction principles.

Thanks to its contactless design, the LS40 achieves sub-micron repeatability while maintaining virtually unlimited mechanical lifecycle, making it an ideal solution for high-frequency dynamic vibration measurements and long-term unattended monitoring applications.

二、Technical Highlights & Specification Advantages

The LS40 is a high-performance linear variable differential transformer (LVDT) sensor engineered for industrial automation, aerospace actuation, and structural health monitoring. With a 40mm full-scale measurement range, it provides non-contact displacement sensing based on electromagnetic induction principles.

Thanks to its contactless design, the LS40 achieves sub-micron repeatability while maintaining virtually unlimited mechanical lifecycle, making it an ideal solution for high-frequency dynamic vibration measurements and long-term unattended monitoring applications.

二、Technical Highlights & Specification Advantages

- Frictionless Measurement Architecture

The sensor’s magnetic core is fully decoupled from the coil assembly, eliminating mechanical wear. This design enables infinite resolution and superior dynamic response, critical for high-bandwidth displacement measurement in real-time control loops. - Exceptional Linearity and Stability

Utilizing precision winding techniques and electromagnetic shielding, the LS40 achieves full-scale linearity error within 0.25% (higher precision optional). This guarantees accurate and reliable displacement feedback for closed-loop control and structural monitoring systems. - Industrial-Grade Stainless Steel Housing

Constructed from 304/316L stainless steel, the enclosure provides outstanding corrosion resistance and EMI immunity. Optional IP67/IP68 ingress protection ensures continuous operation in oil-contaminated, dusty, or high-humidity environments. - Broad Environmental Compatibility

The sensor supports a standard operating temperature range of -40°C to +125°C, suitable for applications from precision laboratory measurements to subsurface exploration instrumentation.

三、Application Domains

- Aerospace Actuator Feedback:

Position sensing for control surfaces and landing gear status monitoring. - Industrial Automation & Production Lines:

Precision workpiece dimension verification and hydraulic cylinder stroke feedback. - Civil Engineering & Structural Testing:

Monitoring cracks, deflections, and displacement in bridges, dams, and large structures. - Valve Position Feedback:

High-precision monitoring of actuated valves in oil & gas pipelines and industrial fluid control systems.